Processing of composites using advanced international processes like :

-

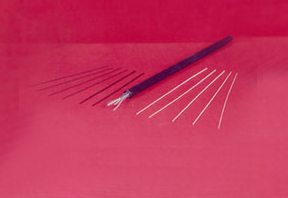

Pultrusion

-

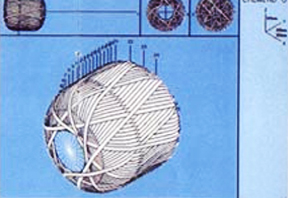

Filament winding

-

Compression moulding

-

Resin Transfer Moulding (RTM) : Using Fiber Glass, Carbon, Aramid and other reinforcements and resin systems like Epoxy, Modar, etc.

Manufacture of process & utility equipment from fiberglass and other composites forms one of the major activities of Kinematics. Major equipment manufactured include tanks, vessels, reactors, agitators, absorption columns,scrubbers, blowers, cooling towers, piping systems etc. In addition to the above Kinematics is also involved in Turnkey execution of small to medium sized process plants and packages like air & water pollution control systems, Filteration systems, Recovery Plants etc. laid strong emphasis on educating its customers & endusers of its products. The result of this has been a strong foundation on which Kinematics stands today.

-

Filament Wound, Pultruded and Compression Moulded